Aero Sun-Times article by Craig Pierson, mid-winter issue, 1980

ABSTRACT

A solar air collector, glass area 103 square feet, was added to the upper level south side of a new home in Billings, Montana. The system includes a blower, but no storage other than the mass of the house. The system is only a fraction of the ideal size to allow total solar heating with storage. It does provide sufficient heat to warm the house to 70° F on sunny fall and winter days, typically keeping the gas furnace off from 9 AM until 8 PM. The project was designed and constructed by the author for $840.00. Provisions were included to allow the collector to act as a summer air conditioner and to be opened for cleaning. Drawings and design analysis are included in this article, with which it is expected the reader could design his or her own project. See photo at end of article.

PROJECT DESCRIPTION

The shingled mansard roof was removed from the proiect area on September 11, 1979, and the materials saved for reuse, for such as for scaffold, new roofs, and a divider wall between the collector and the old roof.

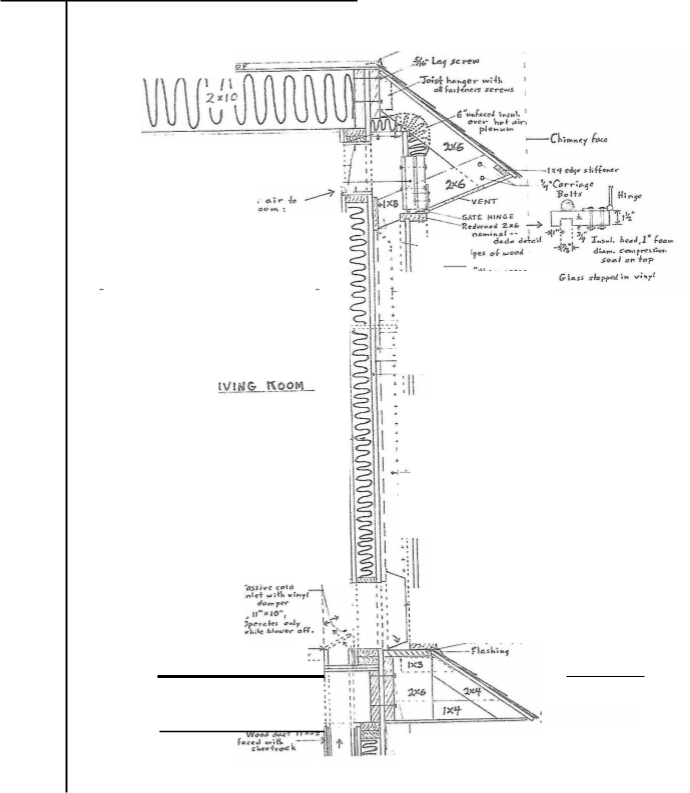

The hot air inlets to the living room were cut and framed, and ten 2X6 trusses were assembled for attachment (with brackets and screws) to the 2 x 8 lag-bolted to the top of the wall [see section drawing]. The 4 x 10 header was first assembled on the ground without glue, and notches were cut for the ten trusses. Four trusses were installed, then the pieces of the header were positioned, glue applied, and bolted together.

Finally, the remaining trusses were added and the hot air plenum was completed and insulated. The plenum includes four small doors (accessible from the living room) to be opened in the summer. Plywood decking, felt, and recycled old shingles completed the top section of the project.

The chimney required finishing with wood siding on the part once hidden by the original mansard. The existing plywood sheathing behind the collector was covered with 15-lb. asphalt felt and 1/2-inch water-resistant sheetrock.

The lower roof section trusses, 2 x 12, 2 x 8, soffit and decking were installed, with the 2 x 8 sloping 1/4 inch from rear to front, to accommodate the swing arc of the windows. The entire collector bottom is flashed to drain possible condensation outside onto the lower roof. A galvanized sheet, 17 inches by 18 feet, was folded and bottom outlet holes were cut on 12-inch centers. This cold air return duct' is smaller in volume at each end, but with smaller outlet holes in the center, higher- pressure area. Sheetrock, metal lath and duct all were painted with Rust-Oleum flat black No. 412, lead free oil based paint.

Window Construction Details

Standard 5/8" x 34" x 76" tempered insulating glass patio door replacements were used. Redwood frames were prepared with dado and rabbeted corners. The sill piece's dado was packed with a 1/4" thick Ethyl-foam shim to transmit the glass weight to the wood frame. An extruded vinyl glazing channel was applied to the glass while it lay flat on a jig, and the redwood frame tapped on, one side at a time. After squareness was verified, the corners were fastened with two 3x10 plated screws. Plywood corner gussets, painted black, were applied across the inside corners of the redwood frames to add strength and help in load distribution. Hinges were bolted to the top of each window unit and the inside wood surfaces painted with gray heat-resisting enamel.

Formica was applied to the outer-edge surfaces which would firmly contact adjacent units, to allow for swing-opening without binding. A vinyl-foam rope was glued to the hinge side to act as a compressible seal against the 4 x 10 header. In mid-October, the windows were installed by screwing the hinge straps into the header. Seals, locks, and trim battens finished the windows, and a plywood soffit with four 60-square-inch vents completed the exterior work.

Air Controls and Operation

All five openings to the interior room are equipped with removable grillwork covered with 2-mil (drycleaner's plastic) membranes. The membranes can drift only one way- toward the room at the hot air inlets, and toward the collector at floor level to admit cool air. In this way, reversed thermo-siphoning cannot occur at night when the air cools in the collector.

Until the sun heats the air to 130°, passive movement transfers cool air from floor level, heats it and discharges it at the ceiling. At 130°, the blower (Dayton 2C 906) is switched on and the rigid dampers in the duct from the basement level family room flip open. Simultaneously, the membrane closes the air inlet at the dining room floor level. Both operations work by action of air pressure; there are no motorized doors. Cool air sinks from the house's upper level down the split entry to the basement level, through louvers in the family room door and, at approximately 60°, into the blower compartment. The blower speed, via Broan (Dayton 4C 254) control, has been adjusted using thermometers, so the air flow will draw out the heat as fast as the sun can provide it, but no faster. Once switched on, the blower runs 4 to 5 hours until the temperature sensor (Dayton 2E 372) finally cools to 70° and stops the motor. Then all dampers drop closed and the collector sits stagnant overnight.

The hot air from the four inlets to the living room averages 120°, for a 60° rise, with about seven collector air changes per minute. The whole house serves as storage since all its air is circulated and heated by the collector.

Heating and Cooling

On sunny fall days it heats the house from 62° to the low 70s, keeping the furnace off from 9 AM to 11 PM. Windy winter days require the furnace in service by 7 p.m. to hold the 68-70° achieved by the system and sun.

The system is too small to store heat for use on cloudy days. Summer cooling will be furnished by reversing the hot air inlet dampers and opening the plenum vents to the soffit, plus opening a north window.

The author acknowledges the valued assistance of the Alternative Energy Resources Organization (AERO) through its staff, library, and the 1979 Passive Solar Design Conference. Certain steps in the work were more than one person could handle. Timely assistance from friends and neighbors is gratefully acknowledged.

References:

Books: FIRST PASSIVE SOLAR HOME AWARDS, HUD; THE SOLAR HOME BOOK, Anderson; THE PASSIVE SOLAR ENERGY BOOK, Mazria. Article: "Natural Convection Collectors," Morris (Solar Age). Review of "Bill 86"- funded projects under Montana's Department of Natural Resources and Conservation.

AUTHOR VITAE

Craig Pierson graduated from the University of Montana (Missoula) in 1967 and received the PhD in Organic Chemistry from Penn State in 1973. After a short tour with the U.S. Army Quartermaster Corps he was appointed Chemist Assistant lab supervisor at the EXXON Oil Refinery in Billings in 1974.

He is founder and president of the Figure skating Club of Billings, a member of the Billings Amateur Hockey League, and various professional and hobby organizations including Elks Lodge 394, BiCEP (Billings Community Energy Program), and AERO (Alternative Energy Resources Organization).